-

AF TTK 130 XRF processing and modelling

AF TTK 130 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx).

XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

-

AF TTK 129 XRF processing and modelling

AF TTK 129 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx).

XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

-

AF TTK 128 XRF processing and modelling

AF TTK 128 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx).

XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

-

AF TTK 127 XRF processing and modelling

AF TTK 127 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx).

XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

-

AF TTK 126 XRF processing and modelling

AF TTK 126 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx).

XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

-

AF TTK 125 XRF processing and modelling

AF TTK 125 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx).

XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

-

AF TTK 124 XRF processing and modelling

AF TTK 124 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx).

XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

-

AF TTK 123 XRF processing and modelling

AF TTK 123 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx).

XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

-

AF TTK 122 XRF processing and modelling

AF TTK 122 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx).

XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

-

AF TTK 121 XRF processing and modelling

AF TTK 121 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx).

XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

-

AF TTK 120 XRF processing and modelling

AF TTK 120 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx).

XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

-

AF TTK 119 XRF processing and modelling

AF TTK 119 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx).

XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

-

AF TTK 118 XRF processing and modelling

AF TTK 118 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx).

XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

-

AF TTK 117 XRF processing and modelling

AF TTK 117 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx).

XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

-

AF TTK 116 XRF processing and modelling

AF TTK 116 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx).

XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

-

AF TTK 115 XRF processing and modelling

AF TTK 115 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx).

XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

-

AF TTK 114 XRF processing and modelling

AF TTK 114 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx).

XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

-

AF TTK 113 XRF processing and modelling

AF TTK 113 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx).

XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

-

AF TTK 112 XRF processing and modelling

AF TTK 112 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx).

XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

-

AF TTK 111 XRF processing and modelling

AF TTK 111 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx).

XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

-

AF TTK 110 XRF processing and modelling

AF TTK 110 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx).

XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

-

AF TTK 109 XRF processing and modelling

AF TTK 109 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx).

XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

-

AF TTK 108 XRF processing and modelling

AF TTK 108 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx).

XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

-

AF TTK 107 XRF processing and modelling

AF TTK 107 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx).

XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

-

AF TTK 106 XRF processing and modelling

AF TTK 106 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx).

XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

-

AF TTK 105 XRF processing and modelling

AF TTK 105 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx).

XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

-

AF TTK 104 XRF processing and modelling

AF TTK 104 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx).

XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

-

AF TTK 103 XRF processing and modelling

AF TTK 103 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx).

XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

-

AF TTK 102 XRF processing and modelling

AF TTK 102 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx).

XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

-

AF TTK 101 XRF processing and modelling

AF TTK 101 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx).

XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

-

AFC TBO STC 117* OM processing and modeling

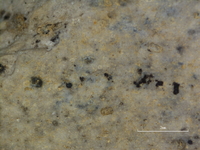

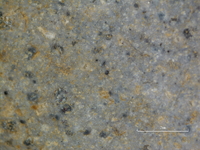

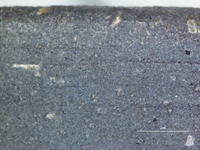

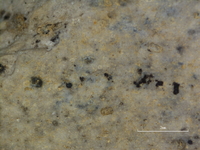

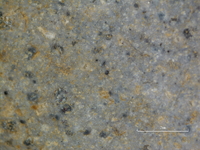

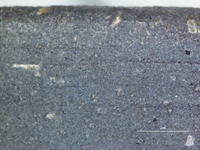

Characterization of pottery shard based on stereomicroscopy. The observations takes in consideration the outer part (front), inner part (back) and the cross section of the shard, characterizing the clay matrix, inclusions and other peculiarities.

-

AF TBO STC 053 OM processing and modeling

Characterization of pottery shard based on stereomicroscopy. The observations takes in consideration the outer part (front), inner part (back) and the cross section of the shard, characterizing the clay matrix, inclusions and other peculiarities.

-

AF TBO STC 052 OM processing and modeling

Characterization of pottery shard based on stereomicroscopy. The observations takes in consideration the outer part (front), inner part (back) and the cross section of the shard, characterizing the clay matrix, inclusions and other peculiarities.

-

AF TBO STC 020* OM processing and modeling

Characterization of pottery shard based on stereomicroscopy. The observations takes in consideration the outer part (front), inner part (back) and the cross section of the shard, characterizing the clay matrix, inclusions and other peculiarities.

-

AF TBO 210 OM processing and modeling

Characterization of pottery shard based on stereomicroscopy. The observations takes in consideration the outer part (front), inner part (back) and the cross section of the shard, characterizing the clay matrix, inclusions and other peculiarities.

-

AF TBO STC 209 OM processing and modeling

Characterization of pottery shard based on stereomicroscopy. The observations takes in consideration the outer part (front), inner part (back) and the cross section of the shard, characterizing the clay matrix, inclusions and other peculiarities.

-

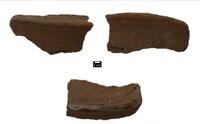

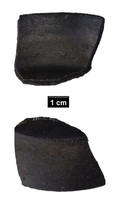

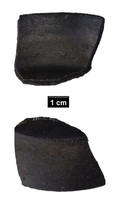

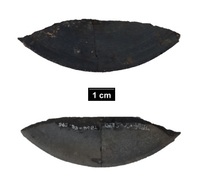

AF TTK 133

AF TTK 133 Yayoi pottery - shard from a jar neck from Tatetski archaeological site.

-

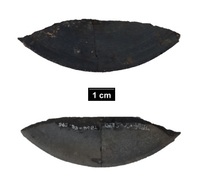

AF TTK 132

AF TTK 132 Yayoi pottery - shard from a jar rim from Tatetski archaeological site.

-

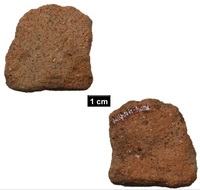

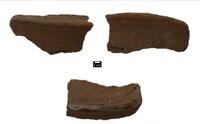

AF TTK 131

AF TTK 131 Yayoi pottery - shard of foot from Tokusyu-Kidai (large ceremonial pot stands), from Tatetski archaeological site.

-

AF TBO STC 175A XRF Data interpretation

XRF data interpretation of metal shard based on elemental composition.

-

AF TBO STC 161A OM Data interpretation

Observation of corrosion products morphology.

-

AF TBO STC 183 CT Data interpretation

Details emerging from the resulting computed tomography and interpretation of 3D volume reconstruction of metal shard.

-

AF TBO STC 175A CT OM Data interpretation

Observation of corrosion products morphology by stereomicroscopy on finding exposed area in order to point details emerging from the resulting computed tomography and interpretation of 3D volume reconstruction of metal shard.

-

AF TBO STC 175A OM Data interpretation

Observation of corrosion products morphology. Finding exposed area in order to perform XRF analysis and computer tomography.

-

AF TBO 174 CT OM Data interpretation

Observation of corrosion products morphology by stereomicroscopy on finding exposed area in order to point details emerging from the resulting computed tomography and interpretation of 3D volume reconstruction of metal shard.

-

AF TBO 167 CT Data interpretation

Details emerging from the resulting computed tomography and interpretation of 3D volume reconstruction of metal shard.

-

AF TBO 166 CT Data interpretation

Details emerging from the resulting computed tomography and interpretation of 3D volume reconstruction of metal shard.

-

AF TBO STC 161A CT Data interpretation

Details emerging from the resulting computed tomography and interpretation of 3D volume reconstruction of metal shard.

-

AF TBO STC 160 CT Data interpretation

Details emerging from the resulting computed tomography and interpretation of 3D volume reconstruction of metal shard.

-

AF TBO STC 160 OM Data interpretation

Observation of corrosion products morphology.

-

AF TBO STC 208 OM processing and modeling

Characterization of pottery shard based on stereomicroscopy. The observations takes in consideration the outer part (front), inner part (back) and the cross section of the shard, characterizing the clay matrix, inclusions and other peculiarities.

-

AF TBO STC 207 OM processing and modeling

Characterization of pottery shard based on stereomicroscopy. The observations takes in consideration the outer part (front), inner part (back) and the cross section of the shard, characterizing the clay matrix, inclusions and other peculiarities.

-

AF TBO STC 206 OM processing and modeling

Characterization of pottery shard based on stereomicroscopy. The observations takes in consideration the outer part (front), inner part (back) and the cross section of the shard, characterizing the clay matrix, inclusions and other peculiarities.

-

AF TBO 205 OM processing and modeling

Characterization of pottery shard based on stereomicroscopy. The observations takes in consideration the outer part (front), inner part (back) and the cross section of the shard, characterizing the clay matrix, inclusions and other peculiarities.

-

AF TBO STC 204 OM processing and modeling

Characterization of pottery shard based on stereomicroscopy. The observations takes in consideration the outer part (front), inner part (back) and the cross section of the shard, characterizing the clay matrix, inclusions and other peculiarities.

-

AF TBO STC 203 OM processing and modeling

Characterization of pottery shard based on stereomicroscopy. The observations takes in consideration the outer part (front), inner part (back) and the cross section of the shard, characterizing the clay matrix, inclusions and other peculiarities.

-

AF TBO 202 OM processing and modeling

Characterization of pottery shard based on stereomicroscopy. The observations takes in consideration the outer part (front), inner part (back) and the cross section of the shard, characterizing the clay matrix, inclusions and other peculiarities.

-

AF TBO STC 201 OM processing and modeling

Characterization of pottery shard based on stereomicroscopy. The observations takes in consideration the outer part (front), inner part (back) and the cross section of the shard, characterizing the clay matrix, inclusions and other peculiarities.

-

AF TBO 169 XRF Data interpretation

XRF data interpretation of metal shard based on elemental composition.

-

AF TBO 169 OM Data interpretation

Observation of corrosion products morphology. Finding exposed area in order to perform XRF analysis or eventually sampling.

-

AF TBO 169 CT Data interpretation

Details emerging from the resulting computed tomography and interpretation of 3D volume reconstruction of metal shard.

-

AF TBO STC 157A OM Data interpretation

Micromorphology of the surface of metal shard.

-

AF TBO STC 157A CT Data interpretation

Details emerging from the resulting computed tomography and interpretation of 3D volume reconstruction of metal shard.

-

AF TBO STC 053 OM acquisition

AF TBO STC 053 OM acquisition Optical microscopy on surface and reflected light microscopy on pottery shard.

-

AF TBO STC 052 OM acquisition

AF TBO STC 052 OM acquisition Optical microscopy on surface and reflected light microscopy on pottery shard.

-

AFC TBO STC 117 OM acquisition

AFC TBO STC 117 OM acquisition Optical microscopy on surface and reflected light microscopy on pottery shard.

-

AF TBO STC 020* OM acquisition

AF TBO STC 020* OM acquisition Optical microscopy on surface and reflected light microscopy on pottery shard.

-

AF TBO 210 OM acquisition

AF TBO 210 OM acquisition Optical microscopy on surface and reflected light microscopy on pottery shard.

-

AF TBO STC 209 OM acquisition

AF TBO STC 209 OM acquisition Optical microscopy on surface and reflected light microscopy on pottery shard.

-

AF TBO STC 208 OM acquisition

AF TBO STC 208 OM acquisition Optical microscopy on surface and reflected light microscopy on pottery shard.

-

AF TBO STC 207 OM acquisition

AF TBO STC 207 OM acquisition Optical microscopy on surface and reflected light microscopy on pottery shard.

-

AF TBO STC 206 OM acquisition

AF TBO STC 206 OM acquisition Optical microscopy on surface and reflected light microscopy on pottery shard.

-

AF TBO 205 OM acquisition

AF TBO 205 OM acquisition Optical microscopy on surface and reflected light microscopy on pottery shard.

-

AF TBO STC 204 OM acquisition

AF TBO STC 204 OM acquisition Optical microscopy on surface and reflected light microscopy on pottery shard.

-

AF TBO STC 203 OM acquisition

AF TBO STC 203 OM acquisition Optical microscopy on surface and reflected light microscopy on pottery shard.

-

AF TBO 202 OM acquisition

AF TBO 202 OM acquisition Optical microscopy on surface and reflected light microscopy on pottery shard.

-

Batch C location

Batch C location All pottery shards found in Area C from Tatetsuki mound site.

-

Batch B location

Batch B location All pottery shards found in Area B from Tatetsuki mound site.

-

Batch A location

Batch A location All pottery shards found in Area A from Tatetsuki mound site.

-

AF TBO STC 201 OM acquisition

AF TBO STC 201 OM acquisition Optical microscopy on surface and reflected light microscopy on pottery shard.

-

AF TBO 169 CT acquisition

X-rays Computed Tomography acquisition of metal shard.

-

AF TBO 167 CT acquisition

X-rays Computed Tomography acquisition of metal shard.

-

AF TBO 166 CT acquisition

X-rays Computed Tomography acquisition of metal shard.

-

AF TBO STC 161A CT acquisition

X-rays Computed Tomography acquisition of metal shard on non-polished and polished (by a soft brush) areas.

-

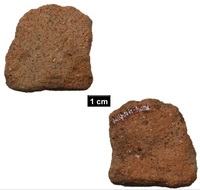

AF TBO 210

AF TBO 210 Debris on rim of lidded dish. (Sue ware). It is difficult to define as part of the body or lid. Found outside the stone chamber (6tr).

-

AF TBO STC 209

AF TBO STC 209 A fragment of the rim of the pedestal plate (Sue ware).

-

AF TBO STC 208

AF TBO STC 208 Bowl foot fragment (Sue ware).

-

AF TBO STC 207

AF TBO STC 207 Pottery fragment (Sue ware).

-

AF TBO STC 206

AF TBO STC 206 Fragment of a foot pedestal (Sue ware).

-

AF TBO 205

AF TBO 205 Dish fragment (Sue ware).

-

AF TBO STC 204

AF TBO STC 204 Haji ware of pedestal dish (low fired earthenware).

-

AF TBO STC 203

AF TBO STC 203 Fragment of a pottery lid (Sue ware).

-

AF TBO 202

AF TBO 202 Haji ware. Pedestal plate (low fire earthenware).

-

AF TBO STC 201

AF TBO STC 201 Fragment of a pottery lid (Sue ware).

-

Tatetsuki and Shimane Pottery - XRPD data

Tatetsuki and Shimane Pottery - XRPD data XRPD data acquired in February 3rd 2021. Data were collected in the 3-80° 2-Theta range by using an automated Rigaku 'MiniFlex' diffractometer with Theta/2-Theta setup in Bragg-Brentano geometry.

Mineralogical analyses were obtained by processing experimentally collected data with the Diffrac Plus (2005) software (EVA 11,00,3).

-

Guidelines for ceramic shard analysis in stereomicroscopy

Guidelines for ceramic shard analysis in stereomicroscopy Optical microscopy on surface and reflected light stereomicroscopy on pottery shard.

The microscopic observation of the fragment was carried out to make a general characterization of ceramic materials. The guidelines applied for the examination of each sample was evaluated:

• The technological class (ceramic)

• The shape and size of the sample (length, width, and thickness)

• The presence of decorations (incisions, impressions, and rims)

• The potential presence of pigment

• The type of paste and its colour

• The amount of inclusions present (low, medium or high)

• The shape (rounded, sub-rounded, sub-angular and angular) and dimensions (fine to coarse) of inclusions

• The presence of iron-oxides

• The potential presence of conservation interventions (glue, gypsum, label ink and label paper)

Instrument: Nikon SMZ745T.

Lens: SM-LW61Ji3 version 3

-

AF TBO STC 175A XRF processing and modeling

Qualitative analysis observing the spectra peaks of the measurements performed on the residual coating of the finding. Finer processing (as quantitative analysis) is prevented by the presence of alteration products and soil on the surface.

-

AF TBO 169 XRF processing and modeling

Qualitative analysis observing the spectra peaks of the measurements performed on the slightly polished area of the finding. Finer processing (as quantitative analysis) is prevented by the presence of alteration products and soil on the surface.

-

AF TTK 101 OM Data interpretation

Micromorphology of the surface of ceramic shard.

-

AF TBO STC 184 OM processing and modeling

Observation of metal shard by stereomicroscopy: exposed area of the shard, type of materials present and alteration products.

AF TTK 130 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

AF TTK 130 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx). AF TTK 129 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

AF TTK 129 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx). AF TTK 128 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

AF TTK 128 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx). AF TTK 127 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

AF TTK 127 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx). AF TTK 126 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

AF TTK 126 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx). AF TTK 125 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

AF TTK 125 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx). AF TTK 124 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

AF TTK 124 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx). AF TTK 123 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

AF TTK 123 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx). AF TTK 122 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

AF TTK 122 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx). AF TTK 121 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

AF TTK 121 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx). AF TTK 120 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

AF TTK 120 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx). AF TTK 119 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

AF TTK 119 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx). AF TTK 118 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

AF TTK 118 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx). AF TTK 117 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

AF TTK 117 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx). AF TTK 116 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

AF TTK 116 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx). AF TTK 115 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

AF TTK 115 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx). AF TTK 114 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

AF TTK 114 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx). AF TTK 113 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

AF TTK 113 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx). AF TTK 112 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

AF TTK 112 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx). AF TTK 111 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

AF TTK 111 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx). AF TTK 110 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).

AF TTK 110 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx). AF TTK 109 XRF processing and modelling XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx).