検索

2073 items

-

AF TTK 122 XRF processing and modelling

XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx). -

AF TTK 123 OM processing and modeling

Incisions description (parallel, curved and even impressions). Inclusions characterization (color, shape and size). Cross section characterization (in case of visible layers). -

AF TTK 123 XRF processing and modelling

XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx). -

AF TTK 124 OM processing and modeling

Incisions description (parallel, curved and even impressions). Inclusions characterization (color, shape and size). Cross section characterization (in case of visible layers). -

AF TTK 124 XRF processing and modelling

XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx). -

AF TTK 125 OM processing and modeling

Incisions description (parallel, curved and even impressions). Inclusions characterization (color, shape and size). Cross section characterization (in case of visible layers). -

AF TTK 125 XRF processing and modelling

XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx). -

AF TTK 126 OM processing and modeling

Incisions description (parallel, curved and even impressions). Inclusions characterization (color, shape and size). Cross section characterization (in case of visible layers). -

AF TTK 126 XRF processing and modelling

XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx). -

AF TTK 127 OM processing and modeling

Incisions description (parallel, curved and even impressions). Inclusions characterization (color, shape and size). Cross section characterization (in case of visible layers). -

AF TTK 127 XRF processing and modelling

XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx). -

AF TTK 128 OM processing and modeling

Incisions description (parallel, curved and even impressions). Inclusions characterization (color, shape and size). Cross section characterization (in case of visible layers). -

AF TTK 128 XRF processing and modelling

XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx). -

AF TTK 129 OM processing and modeling

Incisions description (parallel, curved and even impressions). Inclusions characterization (color, shape and size). Cross section characterization (in case of visible layers). -

AF TTK 129 XRF processing and modelling

XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx). -

AF TTK 130 OM processing and modeling

Incisions description (parallel, curved and even impressions). Inclusions characterization (color, shape and size). Cross section characterization (in case of visible layers). -

AF TTK 130 XRF processing and modelling

XRF quantitative analysis processed by Olympus Vanta software. "Name" is referred to the shard code with a progressive number indicating different measurements spots. "Note" shows the location of measurement spots. The values of the elements are expressed as a percentage by weight. "LE" means light elements i.e. the amount of elements not detectable (Tatetsuki pottery Vanta chemistry XRF results.xlsx). XRF quantitative analysis processed by Olympus Vanta software converted into oxides: SiO2, Al2O3, Fe2O3, CaO, MgO, K2O and TiO2. The conversion to oxides is obtained by multiplying the weight concentration of the element by a conversion factor derived from the ratio of molecular weight of the chosen oxide divided by the atomic weight of the elements. (Tatetsuki pottery Vanta chemistry XRF oxides results.xlsx). -

AF TTK 131

Yayoi pottery - shard of foot from Tokusyu-Kidai (large ceremonial pot stands), from Tatetski archaeological site. -

AF TTK 132

Yayoi pottery - shard from a jar rim from Tatetski archaeological site. -

AF TTK 133

Yayoi pottery - shard from a jar neck from Tatetski archaeological site. -

AF UEN 001

Yayoi pottery - shard of Tokusyu-Tsubo (large ceremonial vessel/jar) from Ueno 1 (Shimane) archaeological site. -

AF UEN 001 ICP-OES acquisition

Procedures for measurements and raw data. -

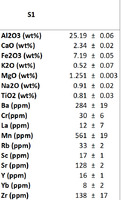

AF UEN 001 ICP-OES interpretation_1

Classification of clay body according to Ca and Mg concentration. -

AF UEN 001 ICP-OES interpretation_2

Composition of AF UEN 001 determined by ICP-OES compared with the one of other coheval fragments found in Kibi and Izumo areas. -

AF UEN 001 ICP-OES processing and modeling

Quantitative elemental composition for major, minor and trace elements